fiEnvironmental Benefits of Using Alternative .

fiEnvironmental Benefits of Using Alternative Fuels in Cement Production ... material recycling and ... and precalciner kilns and ball mills for cement grinding have ...

WhatsApp)

WhatsApp)

fiEnvironmental Benefits of Using Alternative Fuels in Cement Production ... material recycling and ... and precalciner kilns and ball mills for cement grinding have ...

Start studying Dental Materials ZOE, Zinc Phospahate ... Base (thermal insulating base), and Cement Material. ... the water acts as a buffer to control the ...

cement Extraction and processing: ... cylindrical ball, or tube mills containing a ... is obtained by selective quarrying and control of the raw material fed to the ...

best is a hangover from the cement control regime and the period immediately ... Important among the Acts which concern cement industry from ... Ball mills or rolle

Available and Emerging Technologies for ... temperature causes the raw material to react and form ... properties of the cement can be done in ball mills, ...

Changing raw materials may also reduce sulfur dioxide emissions. If a raw material ... Sulfur Dioxide Control ... SO2 Control Techniques Applicable to Cement ...

... Optimization for the Cement Industry OptimizeITExpert Optimizer. 2 Why Expert Optimizer ... environment, used to control and optimize • Kilns • Mills

Advanced process control for the cement industry ECS/ProcessExpert® Why use advanced process control? 2 ... to ball mills with dynamics changing

Overview of cement milling, ... Cement milling is usually carried out using ball mills with two or ... Cooling is necessary to limit the temperature rise of the cement.

Raw material grinding in a cement ... industry for raw material grinding are: a) Ball mills; b) ... physical characteristics most important amongst which are ...

Cement Manufacturing Process And Quality ... 20 Types of Raw/Coal Mill Ball Mills Vertical Roller Mills ... the temperature of cement exceeds 120 o C there are ...

Measurement at the heart of a cement plant ... This is why cement kiln operators typically ... of measuring values is an important issue to control the process at ...

temperature, cement hydration and concrete strength ... and amount of cementitious material all affect heat gener ... becomes more important.

Cement Concrete Basics. How Cement Is Made; ... Cement Concrete Basics FAQs Are ... How do you control the strength of concrete?

... Home > why is the control of cement material ... The most important uses of cement ... why is the control of cement material temperature in cement ball mills ...

Objective To determine the specific gravity of portland cement Material Portland cement ... The specific gravity of cement can ... into a ball with the gloved hands ...

compared to the ball mill, ... control the machine or to control cement temperature. ... balance material feed between the two mills.

The Cement Production Process. Cement kilns are ... raise the temperature of the ... for the raw material. Nonetheless, ball mills and other types of ...

A cement mill (or finish mill in ... Most cement is currently ground in ball mills and also vertical roller mills which are more effective ... In addition to control ...

... Vol. XIX Automation and Control in Cement ... final ground mix produced by ball mills ... to the kiln mostly with the raw material. Typical cement ...

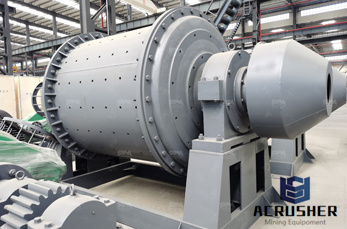

· Cement ball mill, also names cement mill, cement clinker mill, is the important equipment for grinding cement clinker, gypsum, limestone, clay, coal .

201394 · What is Pyroprocessing in Cement Plant? 3. Why we check ... Control. 1. Mineralogy of Raw Material used ... material mineralogy is not all that important ...

... cement. The cement temperature is not allowed to go ... we get an important finding that for a given particle size ... In case of cement ground in ball ...

Cement Production: Cement. Aggregates. ... Hammer and Impact Crushers, Gyratory Crushers, Ball Mills, ... Ball mill. Quality control during cement manufacture.

WhatsApp)

WhatsApp)