Dispersants in Stirred Ball Mill Grinding | Request PDF

Dispersants in Stirred Ball Mill ... It has been indicated that a more viscous slurry should be preferred in the grinding operation to improve the grinding rate ...

WhatsApp)

WhatsApp)

Dispersants in Stirred Ball Mill ... It has been indicated that a more viscous slurry should be preferred in the grinding operation to improve the grinding rate ...

The IsaMill is a stirredmedium grinding mill, ... (such as ball mills and rod mills). Stirred mills often consist ... such as occurs during the operation of tower mills.

Operating method and stirred ball mill of the stirring ball mill . Info ... B — PERFORMING OPERATIONS; ...

Feb 21, 1990 The stirred ball mill, also referred to as an attrition mill or Attritor, is The stirred ball mill ''s operation is simple and effective, ...

The inlet side (5) and the mill housing enclosing a rotatable stirring shaft (4) is disposed horizontally, and grinding bodies (M) is housed was milling chamber (3 ...

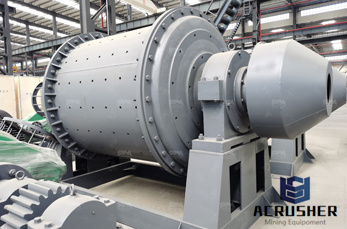

Production Type Stirred Ball Mill Lab ball mills,Lab ... Production type stirred ball mill mainly consist of jar with inner grinding media, stirring device and ...

FINE GRINDING IN THE AUSTRALIAN MINING INDUSTRY ... is the only highspeed stirred mill in operation in the minerals industry. ... liners in ball mills.

Mining On Top: Stockholm 2013 2627 Nov 2013 Stirred milling machine development and application expansion – Graham Davey, Metso Minerals; Senior Process Manag.

tonnage base metal operation. ... ball mill circuit and HPGR stirred mill circuit were determined from a pilotscale HPGR and stirred mill test, ...

stirred ball mill operation. STIRRED MILLS POWER MODELLING Such high probabilities do not exist in the conventional ball mills .

Contact Union Process for the answer to your toughest high energy ball milling ... stirred ball mills" or ... for your operation ...

On going research at the University of Alabama has shown that stirred ball mill grinding is the highest cost unit operation in the beneficiation of Eastern Oil Shales.

In stirred mills, the Hukki ... Ball mill A typical type of ... It is similar in operation to a SAG mill as described below but does not use steel balls in the mill.

Stirred Milling machine development and application extension ... What is a stirred mill? 4 ... •Trend is for single stage ball mill to save CAPEX, ...

Jun 21, 2016· Stirred ball mill Tencan Powder. Loading ... Working principle of Ball Mill /ball cement milling ... Overflow Discharge Ball Mill in Operation Mineral ...

Grinding Classification Circuits. ... for vertical mills during operation. ... to replace a wet horizontal ball mill with a wet vertical mill (stirred), ...

application ranges for ball mills and stirred mill. The Vertimill is always more efficient ... The effective operation of the SMD requires the following

youtube ball mill operation ... YouTube . which is a stirredball mill for grinding small amounts of chocolate ... » Learn More. Operation Manual of Ball Mill.

Attritor Stirred Ball Mill | Sepor stirred ball mill operation,The Attritor mills can be operated in a batch or continuous mode, utilizing either dry grinding or ...

Operation of the stirred ball mill is sim ple and effective. Material to be ground is Key Importan dynamic impingement. ce rms uct. swely ror wet grinding ...

Lab stirred ball mill mainly consist of jar with inner grinding media, stirring device and other auxiliary devices such as recycling device, cooling device, timing ...

comparison of grinding performance between stirred mill and ball mill stirred ball mill operation,The sample screened 425+300 ?m mono size group was ground in the ...

The sample screened 425+300 µm mono size group was ground in the stirred and the ball mill at ... operation and it ... scale stirred mill and ball mill ...

As mentioned earlier, the stirred ball mill term is often used as it depicts a grinding mill, which utilizes a stationary vessel. ... >> mini mill operation

WhatsApp)

WhatsApp)