Ball Mill | Progressive Industries, Inc.

A Ball Mill grinds material by rotating a cylinder with steel grinding balls causing the balls to fall back into the cylinder and onto the material to be g

WhatsApp)

WhatsApp)

A Ball Mill grinds material by rotating a cylinder with steel grinding balls causing the balls to fall back into the cylinder and onto the material to be g

Video embedded· Common types of grinding mills include Ball ... In the cement industry, a ball mill for this ... The opening in the center is used to charge balls into the mill.

Check Your Balls. Here are all the elements you should check to see if you have a ball from a ball mill or a genuine Napoleonic British cannon ball.

Chemical Considerations. The raw material preparation stage of cement manufacture results in the production of a rawmix that is in a suitable state for feeding to the ...

Cement Mill Ball Mill Dynamics ... The vast majority of cement plants in North America use " diameter balls as the largest ball in cement finish mills.

The Emax is an entirely new type of ball mill for high energy milling. The Emax combines high friction and impact to create extremely fine particles.

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing ...

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for ...

Ball mill | Catalog. Mill''s internals, technical aspects of raw and finish mill exploitation in cement industry. Ball mills are the most commonly used machines for ...

Used Ball Mill Sale, Mill Balls, ... Ball Mill Machine, Cement Mill Grinding Balls, Wet Ball Mill. Cement Ball Mill. Ball Mill, Ball Mill Prices, Small Ball Mill for ...

International journal of advanced scientific and technical research Issue 4 volume 1, JanuaryFebruary 2014 Available online on ...

How is cement manufactured? Learn cement manufacturing process thoroughly.

Allis Chalmers Svedala ball mill, 13'' diameter x 21'' long, rubberlined mill, with SiemensAllis 2,000 HP, 4000 volt, 200 RPM synchronous motor, Eaton airflex clutch.

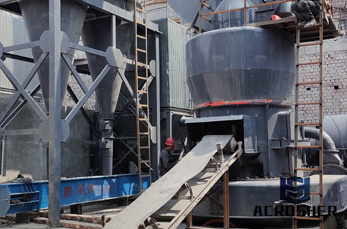

The ball mill is a key equipment to grind the crushed materials, which is widely used in the manufacture industries, such as cement, silicate, new building material ...

Available in 50Lb bags, the Loucast 3000 castable refractory is designed to withstand high Sulphur fuel, erosion abrasion. Buy today from Sheffield Pottery!

Pipes Used To Flow The Zinc Ore In Ball Mill . ball mills friend,ball mills from chokolate – ? used chocolate ball mill ? pipes used to flow the zinc ore ...

The ball mill is a key piece of equipment for grinding crushed materials, and is widely used in production of powders such as cement, silicates, refractory material, and glass ceramics, as well as for ore dressing of both ferrous and nonferrous metals.

Open Type Sand Mills are used in processing enamels, cement primers and emulsions. Apart from this, our sand mills are utilized for processing a wide variety of ...

Grinding media. Grinding balls are only one type of grinding media. Grinding media are the means used to crush or grind material (cement, mineral, .) in a mill.

Used Ball Mills for ... industries such as cement, ... mill with the use of metallic or steel balls or other media has been used in single stage ...

Unused FL Smidth wet grind overflow ball mill, 27'' ( m) diameter x 46'' ( m) long. Discharge with MW (20,500 kW) gearless wrap around motor drive, 50 Hz ...

2003). These models can be used to simulate cement grinding circuits and to assist their optimisation. The "work horse" of the cement grinding plant is the two ...

Bolted shell liners, tube mill internals, boltless shell liners for cement mills from AIA Engineering Ltd.

Design and Optimization of Ball Mill for Clinker ... For commercial cement plant ball mill 12 m ... use of topside ball size 130 mm ( topside 90 mm balls used ...

WhatsApp)

WhatsApp)